Customized

Solutions for Various Industries

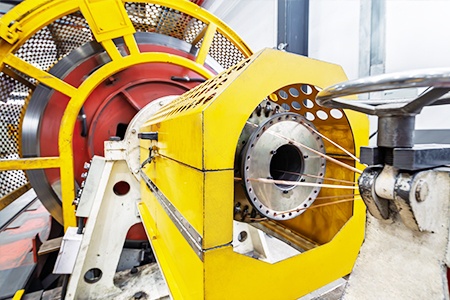

We manufacture high performance power cables, power cords and accessories specified for various applications for the efficiency and security of the power sector.

/